Supply Chain Management Process of Starbucks

More

and more companies are concentrating on creating a sustainable supply chain

process in their operation network and using the resources to its maximum

capacity. A growth of conscious consumers has further facilitated this process

as more and more consumers want companies to lay stress on environmental and

sustainable factors. The actual transformation occurred in the year 2008 and

the main approach used by the company was the integration of various processes

that allowed them to achieve a long term profit. These processed were social,

environmental and economic process whereby Starbucks could develop a proper

SSCM network

The Findings

After

recognizing and evaluation the current supply chain which Starbucks had at that

point of time, the Senior Vice President Gibbons found out that more than half

of the delivery of raw material to the store were arriving late. Gibbons

visited several Starbucks store himself and analyzed that the employees were

not paying much attention to when and how the raw materials arrived. Thus there

was clearly room for improvement. He also analyzed the cost process and

recognized that the main factor for cost inflation was the involvement of third-party

logistics. Starbucks outsourced almost 65% of its ingredients in order to speed

up the operations process. But in doing so, the agreements, contracts,

transport cost were causing delays and cost inflation of the products

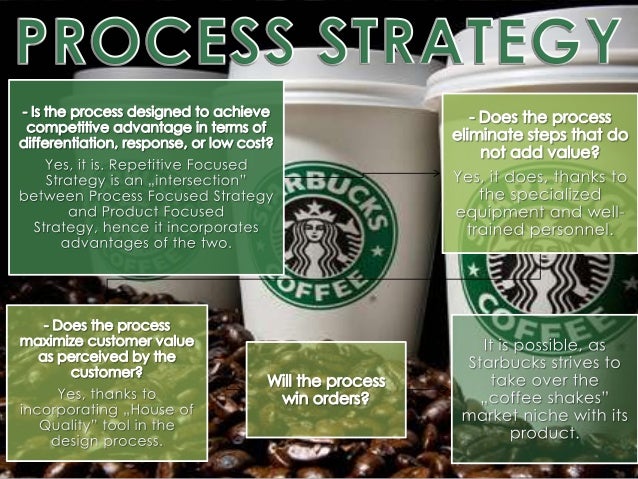

Operational Strategy and Macro Environment

Although

the findings and the three-step plan were pretty direct, the design of each

part of the process was extremely complicated according to Gibbons. He tried to

simplify the entire process so that the whole system would fall into four basic

structure; plan, source, make and deliver. For example, if an employee were to

be involved in planning, he or she would be put under an umbrella of the planning

group, which would involve planning as a whole; be its production planning,

recipe planning or packaging planning. The sourcing activities were grouped

into two areas of ‘coffee’ and ‘non-coffee’. This was an easier and direct

method understandable to all. Statistical data showed that Starbucks spent

almost 600 million US Dollar on the sourcing of raw materials just for coffee.

The ‘non-coffee’ sourcing amounted to 2.5 billion US Dollar annually

The

manufacturing team at Starbucks also devised a more efficient model whereby

they could deliver coffee beans to the processing plants in a timely manner.

Starbucks opened processing plants in areas where the coffee originated. This

was one of the critical processes that reduced time and cost and increased

efficiency in a major way. According to Schönberger

et al (2019) Starbucks already owned three coffee plants in the US, the

fourth one in Columbia. Attempts and planning were made to open in other areas

of Africa and Latin America, where it sourced its coffee from. Additionally,

the company opened a plant in Amsterdam, the Netherlands for its coffee

processing in Europe and also developed 24 new co-suppliers for various raw

materials. In the cost analysis process, Gibbons saw identified that

transportation, logistics and distribution made up the major part of the expense.

The reason was inevitable because its coffee was sourced from various parts of

the world like Ghana, Venezuela, Uruguay, China, the Middle East and other

regions. This proved to be the most challenging part of Starbucks. Data

indicated that per week Starbucks had almost 70,000 to 80,000 international

delivery made mainly by sea shipment.

The

solution here again was the introduction of a single logistics system, which

would bring processed coffee beans from all over the world in sea shipments to

Europe, UK and the US. From the port, the green beans would be transported to

the storage sites which were then taken to roasting plants. After they were

roasted, they were packed and transported to the distribution centres

regionally. The distribution centres were managed by third-party companies, who

delivered the products to the retail outlets. Contract rates of these third-party

companies were reviewed and negotiated for better pricing. Clear cost metrics,

production metrics and the service metrics were clearly outlined.

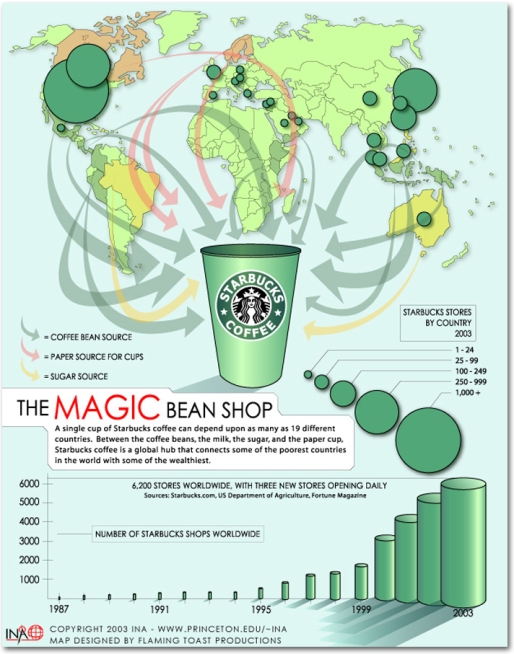

Sourcing Map of various products at Starbucks

Key Requirements, Capabilities and Challenges

In

order to cope up with the above-mentioned strategies, Starbucks had to

formulate certain key requirements which they needed to maintain at all cost.

One of the areas that were mentioned earlier was the fact that the employees

working at the retail store did not pay attention to when and how the raw

materials arrived. This clearly proved a need for proper training. Although the

training was provided to all employees, certain gaps were identified which made

them lose interest in all parts of the process. To quote what Howard Schultz

said, “these people are not only the heart and soul but also the public face of

the company. Every dollar earned passes through their hands.”

The

training of the employees was increased to being more than just a server at a

retail store. They were encouraged to learn more about speciality coffees and

their origin. Employee focus was directed to this by increasing the health care

benefits of everyone who were working for 20 hours or more per week. By doing

so, they not only attracted higher quality employees but also improved the

turnover rate and the overall cost spent on the employees. CSR activities were

also introduced at the various retail outlets. Various other plans like the

Bean Stock were introduced, which would grant stock options to every employee,

from top managers to servers

The

quality of coffee beans also had to be maintained as cost in logistics and

deliveries were reduced. Starbucks bought about a social change in the

suppliers by conducting tie-up with conservation organisations such as

Conservation International. This strategic collaboration facilitated the

establishment of CARE (Coffee and Farmer Equity Practices). This practice

ensured farmers were treated ethically and had the chance to improve their life

by offering high-quality coffee

The

major challenges that were faced while improving the supply chain process were

dealing with logistics and the distribution centres. The huge volume of their

business proved to be quite tough to handle. The distribution centres alone

were 200,000 to 300,000 square feet in size. Deliveries made per week were also

70,000 in numbers. The main areas of the challenge here were the product

transition, the introduction of new products and the promotion of the same

Analysis and Evaluation

From

the above discussion, it is clear that Starbucks developed many strategies

which would improve their supply chain processes. These strategies were just

only a part of other strategies that were incorporated along with the changing

time. However, the most important factor that Starbucks developed in the minds

of its customer is the feeling of community. Many scholars like Esteban et al(2019) state this feeling as the

‘third place’. This ‘third place’ was a representation of a corner or a place

where customers could forget their daily routine and sit and relax with a quiet

cup of coffee. The design analysis as mentioned earlier here is important as

store designs were made keeping in mind this feeling of a special place. Other

four Vs also contributed significantly as improved in the supply chain process

automatically improved volume and dependability. Once the supply chain was

managed, the marketing team could also concentrate on creating variation and

flexibility strategies for the customers.

Other

factors that further supported this concept of ‘third place’ was the increase

of passive income opportunities and the availability of free Wi-Fi available at

all their stores. Mobile computing devices with every individual also made

access to the internet possible. This further added to the flexibility that

they provided to the public in general

Starbucks Future Includes More Mobile, More Food, More China, and More Veterans

Recommendations

When

considering the challenges mentioned earlier, the major recommendation here

would be to break down the entire process into smaller sub-parts so that

handling of the operations would be easier. The strategies created here laid

the foundation of the entire process, but for the continuation of effective

handling, sub-departments had to be introduced. The processes also had to

maintain transparency in their operations and hence has to incorporate

procedures so that the supply chain partners maintain transparency and

reliability

Conclusion

The

supply chain management system in Starbucks uses several technologies which are

essential for efficient management. High-quality digital technology with

automated information system is integrated into all its retail stores as well

in various distribution centres and processing plants

References

Comments

Post a Comment